AI in Production: Successfully Starting with Process Optimization

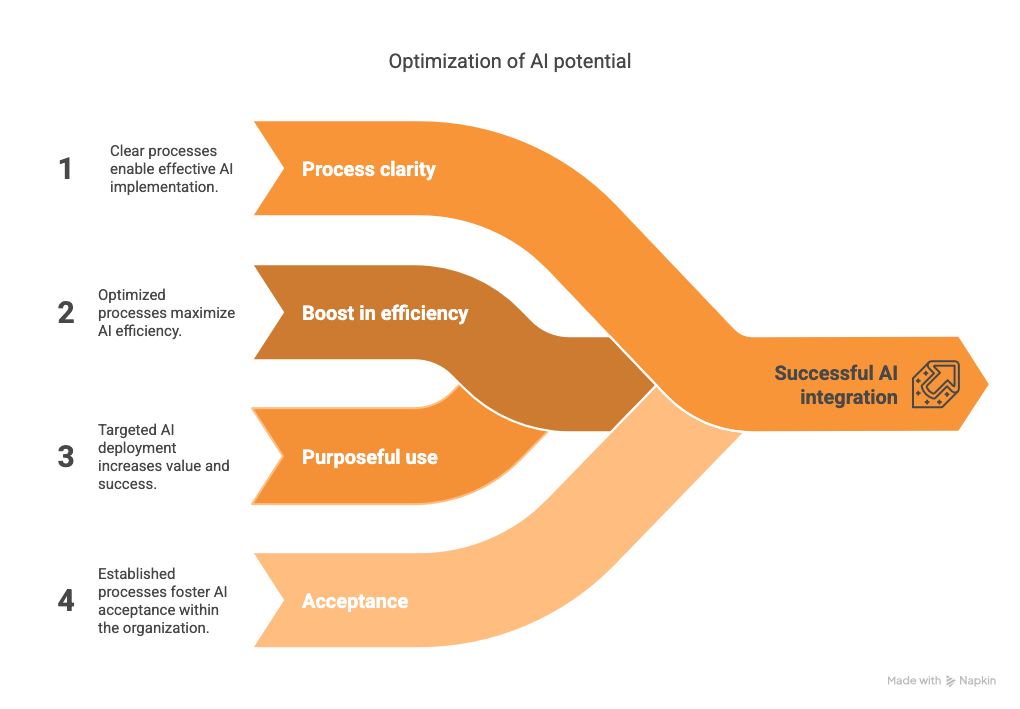

The implementation of Artificial Intelligence (AI) in production is a key component of digital transformation and Industry 4.0. Manufacturers expect increased efficiency, automated workflows, and data-driven decision-making. However, before AI models can be effectively implemented, process optimization and clear documentation of existing processes are essential.

Why is process optimization crucial before AI implementation?

Clear structures provide the foundation for data-driven AI systems.

Artificial Intelligence in manufacturing relies on structured, high-quality data. When processes are not documented or are unclear, data gaps and sources of error arise. Systematic process digitization and optimization ensure that AI models operate on a solid foundation.

Inefficient processes are not automatically improved by AI.

A common misconception: AI "solves" inefficient workflows. In reality, it often just scales them. When companies automate error-prone or unnecessarily complex processes with AI, the problem is exacerbated rather than solved. Only an optimized process landscape makes AI deployment truly effective.

Targeted AI Deployment through a Solid Understanding of Processes

When production processes are clearly described and analyzed, specific areas for AI application can be identified – for example, in predictive maintenance, automated quality inspection, production planning, or real-time error detection.

Employee Acceptance through Transparent Processes

Changes in production – such as through AI – are only accepted when they are understandable. Optimized processes create transparency and trust. Employees recognize the benefits of the technology and perceive it as support rather than a threat.

Successful project management for leading industrial companies

FAQ - Introduction of AI in Production

Here you will find answers to frequently asked questions (FAQ) that companies should consider before implementing AI solutions.

Process optimization refers to the targeted analysis and improvement of existing workflows in production. In the context of Artificial Intelligence (AI), it forms the foundation for creating clear data structures, stable processes, and automatable steps. Without prior optimization, AI applications cannot function reliably.

The introduction of AI in industry requires high-quality, structured data. If processes are not clearly defined or are inefficient, AI systems may deliver incorrect or incomplete results. A well-documented and optimized process landscape forms the foundation for successful AI projects.

The use of Artificial Intelligence in manufacturing can, among other things:

- Improve production planning,

- Detect sources of error early (Predictive Quality),

- Predict maintenance needs (Predictive Maintenance),

- Use resources more efficiently, and

- Automate processes.

The prerequisite is always a solid process foundation.

AI makes sense when processes are digitally captured, standardized, and sufficient data is available. Even for medium-sized companies with complex workflows, initial use cases can be valuable – for example, in quality control or maintenance.

The first step is a detailed process analysis. This helps uncover optimization potential and assess where AI can be effectively applied. Following this, pilot projects that are scalable are implemented. The key is: The focus is not on the technology itself, but on the tangible benefits for the business.

Depending on the use case, AI requires:

- Machine data (e.g., sensors, run times)

- Production data (e.g., production volumes, error rates)

- Maintenance and quality data

- Potentially ERP or MES system data

- IoT data of all types

The more structured and historical the data, the better the algorithms can be trained.

ion3 analyzes your supplier contracts and negotiation processes. Through long-term agreements and competitive tendering procedures (RFP), we help reduce your procurement costs. Additionally, we work with you to optimize order quantities and cycles to minimize overproduction and inventory costs.

Innovation is a key competitive advantage. ion3 organizes innovation workshops and joint development projects with your suppliers. We create incentive systems that promote innovation and integrate new production methods and materials into your supply chain.

ion3 works based on clear sustainability criteria, which are integrated into the supplier selection and evaluation process. We promote collaboration with suppliers who encourage sustainable production methods and contribute to reducing the ecological footprint. Audits and regular reports ensure that high standards are maintained.

Yes, small and medium-sized enterprises (SMEs) can also benefit from AI, especially if they have already taken steps towards digitalization. The key is a clear, pragmatic approach with manageable projects and measurable benefits.

AI is changing work processes and requirements – training helps reduce fears, recognize potential, and use AI effectively.

What should be trained:

- Basic understanding of AI and machine learning

- Application examples in one's own work area

- Handling of tools (e.g., ChatGPT, Copilot, automation tools)

- Data protection & ethical aspects

Note: As of February 2025, training is mandatory:

European Commission (2024): Regulation on establishing harmonized rules for artificial intelligence (AI Act), Article 29.

https://eur-lex.europa.eu (Accessed on: April 10, 2025)

Any questions about AI in production?

Do you want to know how Artificial Intelligence can make your production processes more efficient, robust, and future-proof? Talk to us!

At ion3, we provide hands-on consulting and tailored solutions – from the initial idea to implementation.