Client: Automotive Supplier

The client develops and manufactures high-performance components using hydroforming technology. As a technology leader, the company supplies leading automotive manufacturers and their suppliers with ready-to-install components for chassis, body, and exhaust systems.

Additionally, the company is a globally leading manufacturer of household appliances, offering a wide range of products including washing machines, dishwashers, and refrigerators. It operates in over 50 countries and is headquartered in Germany.

Identified Issues at Project Start

At the start of the project, several key challenges were identified:

In logistics, there were difficulties in ensuring reliable material availability and maintaining correct batch sequencing. High inventory levels led to increased storage costs due to surplus stock and inefficient range alignment. The lack of clear delivery concepts hindered both planning and production execution.

In terms of downtimes and waiting times, inconsistencies emerged from varying batch characteristics. These were intensified by missing process documentation and insufficient process descriptions.

In the press shop, the absence of an effective KPI system, poor visualization of output, and unreliable data collection created further inefficiencies.

Quality assurance lacked clearly defined quality metrics. In production planning, issues included suboptimal batch sizes, inefficient sequencing, lack of synchronization, and misaligned target settings.

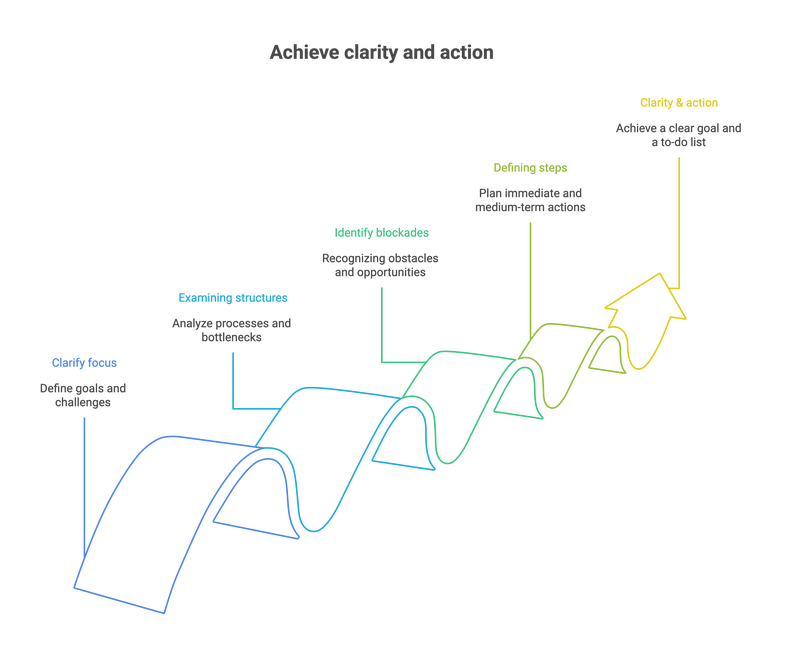

Solution Approach

As part of the process optimization and Lean Management initiative, production data visualization was implemented across all presses. This included counters for piece output and documentation of downtimes and waiting periods.

Based on the collected data, a detailed analysis of interruptions and delays was conducted to derive targeted measures for efficiency improvement.

Simultaneously, a pilot project was launched to integrate production planning for Hydroforming Press 1 and Press 2 into the ERP system.

To support this transition, new planning rules were introduced, and outdated orders were cleaned up and updated within the system.

The implementation of Lean Management served as a core framework for optimizing planning processes and increasing overall efficiency. Additionally, the maintenance strategy was revised, resulting in reduced downtimes.

Measured Results

Improvements were measured using data from the previous year. Over a two-month period, changes were documented, analyzed, and compared to historical data.

As a result of the implemented measures, each press achieved an average efficiency increase of 30% compared to the prior year.